This standard defines a general laboratory test method for determining the air permeability of building components or building elements.

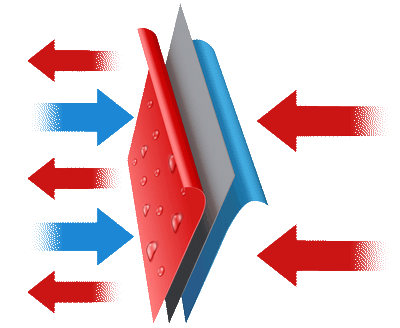

Air permeability is an important performance characteristic for many types of building envelopes. The general test method given in the standard sets out the main features for the laboratory testing of air permeability of building components and parts of building envelopes.

Except where specific products have properties which make application of this standard difficult, this standard should be used as the reference by all harmonised product specifications.

Principle

A set of pressure difference steps (positive and/or negative) is applied across the specimen and the air flow rate through the specimen is measured at each step. The measurement results are corrected to reference conditions. A graph of air flow rate versus pressure difference is drawn. When appropriate, the leakage coefficients characterising the building component are derived from the measured results.

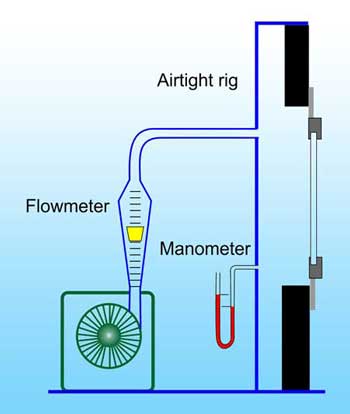

Apparatus

The test apparatus shall include the following

The test apparatus shall include the following

a) a rig for fitting the test specimen;

b) a way to apply a controlled air pressure difference over the test specimen;

c) a way to of create changes of air pressure differences

d) the ability to measure the air flow

e) a way to measure the air pressure differences

f) The ability to seal the joints of the test specimen

Procedure

The test is dependent on the air-tightness of the test rig and is performed with positive pressure differences and, if required, with negative pressure. There is also a system for non-airtight test rigs.

Measurement

Three pressure pulses need to be applied. Each pulse shall be maintained for at least three seconds. Each pulse must create a stabilised pressure difference greater than the maximum pressure difference of the test.

The air pressure differences are applied over several steps depending on the products specification.

The measurements are used to determine the air tightness via a standard process and formula.