Plant Respiration

Plant Respiration

Fruit, vegetables and green plants all respire (plants also photosynthesize,which is the same chemical process but in reverse).

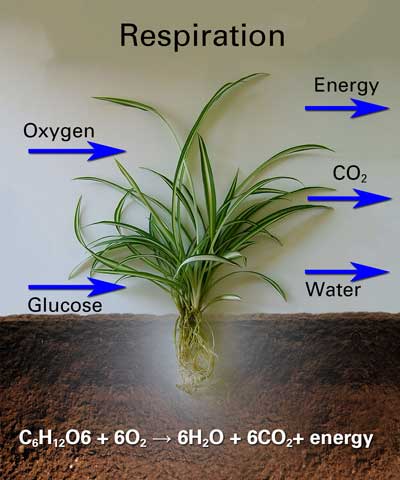

Respiration uses oxygen and releases the energy stored in the plant's carbohydrates - and this process produces both carbon dioxide and water.

C6H12O6 + 6O2 → 6H2O + 6CO2 (+energy) or in words

glucose + oxygen → water + carbon dioxide (+ energy)

Unlike growing plants that both respire and photosynthesize, picked vegetables and fruit only respire.

Respiration involves a complex series of reactions. First, glucose is oxidized, then the chemical's bonding energy is transferred to the plant's adenosine triphosphate (ATP) molecules. ATP then uses this energy to complete a series of specific tasks within the cell, resulting in the release of carbon dioxide and water.

Respiration changes the delicate packaged (or unpackaged) atmosphere that surrounds the fruit and vegetables. Even relatively small changes in this environment can make a large and disproportionate change in shelf life, quality, freshness, taste, texture and appearance. This is especially true for Modified Atmosphere Packaging (MAP) but it is also true for non-MAP packed produce during the storage, packaging, transport and display cycle. The rate of respiration is also dependant on temperature.

(Fortunately, growing plants use more carbon dioxide in photosynthesis than they create during respiration, and produce more oxygen while photosynthesising than they use during while respiring thus, unlike picked fruit and vegetable, they are a net producer of oxygen and a consumer of carbon dioxide.)

The solution for fruit and vegetables to their respiration and short-shelf life problems is two-fold.

First; you need to measure their respiration rates, for example with our Versaperm plant respiration monitor system which allows you to measure the rates of production and consumption of oxygen, carbon dioxide and water vapour (humidity). You can do this, for both unpackaged and packaged produce, over a wide temperature range (-20 °C to 65 °C, in intervals as small as 0.1°C).

Second; for both traditional and MAP packaged produce you need to measure the oxygen, carbon dioxide and water vapour permeabilities of the packaging material you use and also of the finished package.

Not only does every type of vegetable and fruit (and even their different species) respire at different rates, but the very delicate balance of gases needed to optimise shelf-life and freshness also varies. Every material and packages has its own very specific balance of vapour permeabilities and overall flow rates for oxygen, carbon dioxide and water vapour. It is only by matching these three permeabilities with the detailed requirement of each fruit or vegetable that shelf life (along with texture, taste and appearance) can be optimised.

If you have insufficient oxygen in the package, atmosphere anaerobic respiration occurs and produces unwanted tastes, odours and a general deterioration in the product. Similarly, excessive carbon dioxide shortens the shelf life of various fruits and vegetables.

There are two main types of packaging – active and passive.

Passive packaging

Passive packaging

If the fruit / vegetable and film permeability characteristics are properly matched, a beneficial atmosphere evolves naturally – or "passively" through the natural consumption of O2 and production of CO2 during respiration. The packaging polymer's permeabilities control the rates of exchange of each gas between the package's contents and the outside environment.

Active Packaging

With active packaging a specific gas mixture can be produced intentionally simply by filling the pack with an appropriate mixture of gases (MAP). This helps to overcome any deficiencies in the passive packaging so that a balance is created faster, or even instantly. Sometimes, additives can be incorporated in the packaging's polymeric film or container to modify the headspace atmosphere and extend the shelf-life.

Alternatively a balance can be created under a partial vacuum simply by reducing the headspace.

In all of these cases the extended shelf life depends on balancing the fruit or vegetable's respiration rates with (primarily) the oxygen, carbon dioxide and water vapour permeabilities of the packaging.

Ethylene and Ripening

Ethylene is a hydrocarbon gas and a plant ripening hormone. It is invisible and odour-free to humans but not only do some fruits produce ethylene as they ripen, but introducing ethylene actually speeds the ripening process in stored fruit ensuring they are ready to go on display.

Versaperm plant respiration measurement can be optimised to measure ethylene if this is required.

For on our plant respiration equipment click here

For information on measuring the permeability - of wax coatings on fruit and vegetables click here

For wikipedia information on cellular respiration click

For a guide to Packaging Fresh Fruit and Vegetables (including ethylene) from the Danish Technological institute, click here

For an article on food and packaging testing click here

For a technical paper on "Effect of surface coatings on the shelf life and quality of know fruits during storage" click here