Welcome to Versaperm – Your Partner in Vapour Permeability Solutions

Versaperm is a global leader in vapour permeability measurement, offering advanced instrumentation, laboratory testing services and expert technical consultancy. We specialize in helping industries measure and control vapour permeability - a critical factor that impacts countless applications across manufacturing, engineering, and product development.

Vapour permeability determines how much vapour can pass through a material. Surprisingly, even similar-looking materials can vary in permeability by factors of thousands or more, depending on the substance and vapour involved. This property plays a vital role in a huge range if industries, including food and pharmaceutical packaging, aerospace, construction, packaging, electronics, and quality control. It can influence the shelf life of products, prevent corrosion, ensure the structural integrity of enclosures, and optimize machinery performance.

At Versaperm, we combine decades of experience with cutting-edge technology to develop highly accurate vapour permeability measurement instruments. Our expertise extends to testing a vast range of materials and gases, making us a trusted partner for both manufacturers and researchers. Beyond instrumentation, our laboratory testing services and consultancy provide valuable insights to optimize materials, improve durability, and drive innovation.

- Extend product durability by reducing moisture-related damage.

- Enhance performance in challenging environments.

- Develop materials tailored to specific applications and industries

- Measure the vapour permeability of any and all legal gases

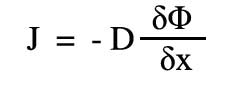

Fick's First Law of Diffusion

Fick's First Law states that 'the rate of diffusion (e.g. of a vapour) is proportional to the surface area and the concentration difference, it is inversely proportional to the thickness of the membrane".....more

Video Link:The Dangers and Benefits of Vapour Permeability Video

Video Link: What is Vapour Permeability

Video Link The Dangers of Vapour Permeability Video

Video Link: The maths and science of vapour permeability

We welcome questions and comments about our products and services, you can reach us as follows:

We welcome questions and comments about our products and services, you can reach us as follows: