The Air Permeability of Window Seals and Double Glazed Units

The Air Permeability and weather performance of windows is traditionally classified to reference to BS 6375-1:2004. Because of the current trend towards high rise buildings BS 6375-1 approved window systems are now being specified in more exposed situations than has been the case in the past. Additionally several window manufacturing companies are also testing their windows to BS EN curtain walling standards so they can be used either as individual windows or as opening lights in external curtain walling systems.

Additionally several window manufacturing companies are also testing their windows to BS EN curtain walling standards so they can be used either as individual windows or as opening lights in external curtain walling systems.

The air permeability differ somewhat between these two (and indeed, other relevant) standards particularly at the higher design pressures which apply to high-exposure sites. BS 6375-1 and EN 12207:2000 (the European standard) are less significant for water tightness and structural resistance to wind.

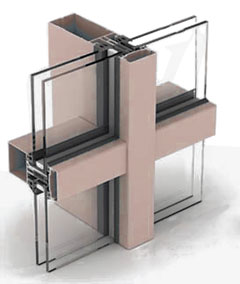

Section of glazed curtain wall showing air-permeability sealing BS 6375-1:2004 : Measures the air leakage of the overall area of the window, and the air leakage along the total length of the opening joint, at the specified test pressure. BS EN 12152:2002 : Only covers fixed panels/lights and sets two acceptable air leakage rates, one by area and one by joint length but with compliance required for both criteria at the specified test pressure. CWCT Standard:2006 : This refers to BS EN 12152, and uses the same permissible air leakage rate of 1.5m3/hr/m2 (i.e. by area) for fixed lights and introduces a CWCT-specific requirement of 2.0 m3/hr/lin.m (i.e. by length of opening joint) for opening lights. Testing the air permeability of seals, components and even finished systems and structures is easy with the latest Versaperm permeability testing equipment. It is fast, easy, accurate and repeatable. Versaperm MKVI Vapour permeability testing instruments are based on a modular approach which is designed to ease customisation. Thus each Vapour permeability testing instrument is built with a variety of options to suit the customer and their particular application. This is achieved at prices which are competitive with mass-produced instruments. Click here for a press release on air permeability testing for double glazing testing.

There are several standards that relate to the Air Permeability and weatherproofing of windows and double and triple glazed units. These include:-

EN 12207:2000 Air Permeability which replaces BS 6375-1:1989 and partially replaces BS 6375-1:1989. Class 3 at 600Pa. or better.

Classification and Guidance for Weather Tightness BS 6375 Part 1: 2004

Windows & Doors, Air Permeability test method BS EN 1026: 2000

Windows & Doors, Air Permeability classification BS EN 12207: 2000

Windows & Doors, Classification for weather tightness and guidance on selection and specification BS 6375-1

For systemised building envelopes the standard is CWCT Standard:2006