Commercial

measurement of Carbon Dioxide (CO2) permeability rates is widespread,

though it is particularly import for carbonated drinks

containers, MAP packaging and corrosion.

Carbonated drinks bottles

Carbonated drinks bottlesThese which are commonly made from polyethylene terephthalate (PET) as this material has good barrier properties against both oxygen and carbon dioxide. Versaperm can measure the CO2 (and other gas) permeability of bottles or containers that are filled with fizzy drinks. It can also measure the permeability of the material in flat sample format. These two measurements are unlikely to be identical due to the thermoforming process, which can increase permeability by several hundred percent!

Controlling the flow or build-up of carbon dioxide can be critical if you are to avoid degradation in many fresh foods. MAP (Modified Atmosphere Packaging) technology can substantially reduce the rate of decay associated with processed fresh vegetable, fruits and other edible products. This leads to both a significant increase in both shelf-life and quality. Using films with the right CO2 (and oxygen etc) permeabilities controls, amongst other things, the respiration rate which is central to the MAP design. Unfortunately the complication of each food or vegetable type needs entirely different permeabilities and what is best for one product may actually speed decay in others. Hence the need for comprehensive testing.

The strength and effectiveness of a pack's seal can also play a part in this. For more information on this aspect click here.

To prevent excessive carbonation of steel, for example in concrete units, they need to be treated with a coating with a low CO2 vapour permeability (i.e. high resistance). A barrier against this CO2 is often needed to avoid carbonation, which leads to severe corrosion and is probably the most critical problem in the durability of concrete structures. At the same time there is also the need for a relatively high permeability (low resistance) for water vapour to allow any vapour to escape from the structure.

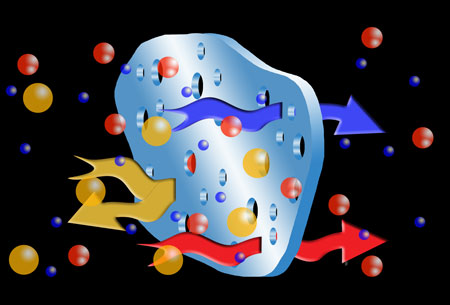

Typically

a specimen is placed in the measurement chamber which separates

the two sides of the material under test. One of these is exposed to a an

inert atmosphere (e.g. a constant flow of nitrogen) while the

other is exposed to CO2. Once a steady state has

been achieved the amount of oxygen in the nitrogen is measured

with any one of a number of sensors (depending on the sensitivity

required) and the permeability is simply read off the screen.

Click here for a link to permeability on Wikipedia

Click here for a link to Carbon Dioxide on Wikipedia

With

the Versaperm meter low permeation rates can be measured quickly

and accurately.

With

the Versaperm meter low permeation rates can be measured quickly

and accurately.

The Carbon Dioxide sensor used depends on the choice of the customer. We use a wide variety of sensors, sourced from market leaders around the world, and are able to build an instrument around a sensor of the customer's choice.

We customise each instrument to meet the range required by the customer's application.