The Versaperm Oxygen Permeability Meter Mk VI is a versatile permeability measuring device and an extremely sensitive and accurate instrument for determining the quantity of oxygen gas passing through or emitting from any material. Its versatility is evident in the number of applications with which it is routinely tasked and the range of industries in which it is used.

The Versaperm Oxygen Permeability Meter Mk VI is a versatile permeability measuring device and an extremely sensitive and accurate instrument for determining the quantity of oxygen gas passing through or emitting from any material. Its versatility is evident in the number of applications with which it is routinely tasked and the range of industries in which it is used.

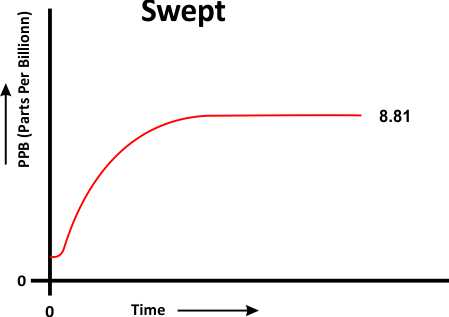

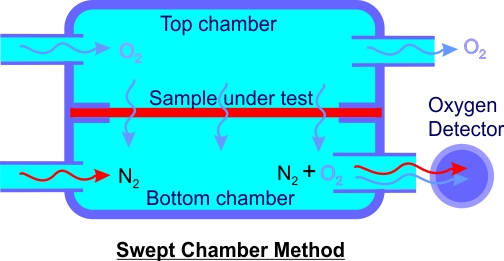

The Meter typically uses the sweep gas method. The diffusion chamber is divided into two sections by a test specimen. Dry nitrogen is passed through one upper part and oxygen is passed through the other. Pure nitrogen is passed into a temperature-controlled cabinet and through a chamber that is often optimised for the type of materials and objects under test. The oxygen gas swept from the chamber is then measured using a sensitive detector. The result is then displayed on the instrument touch-screen for further analysis. A wide range of O2 sensors is available to match different applications

The original Permeability Meter was developed for measuring packaging materials with very low gas permeability transmission rates but more permeable barriers can also be measured with speed and accuracy.

The permeability of boards up to 38 mm thick can also be measured. Paint films and other surface treatments can also be measured by applying them to typical substrates such as plywood, hardboard, etc.

The permeability of boards up to 38 mm thick can also be measured. Paint films and other surface treatments can also be measured by applying them to typical substrates such as plywood, hardboard, etc.

By means of a secondary chamber the rate of gas loss through surfaces and/or seals from containers up to 110 mm dia x 200 mm long in the normal large bottle chamber can be measured. Larger chambers can also be supplied. A small chamber option is also available, which is attached to the diffusion chamber, and provides a faster reading of the gas loss from small bottles, sachets and blister packs.

Please contact us to discuss how we can meet your needs.