Swept Gas Method

Swept Gas Method

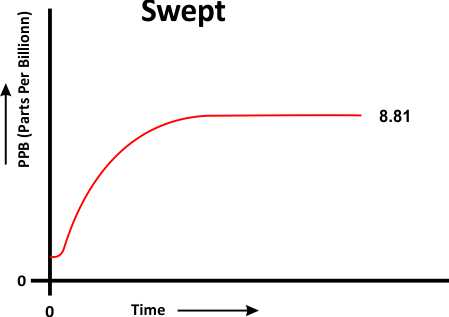

The swept gas technique for measuring vapour permeability is, today, probably the most widely used across all forms of gas permeation measurement. In this method the sample is clamped between the two parts of a "measurement" or "diffusion" chamber where it acts as a vapour barrier. The gas under test is placed on one side of the barrier, within a temperature controlled environment. As the gas permeates through the barrier i is transported to a sensor. The concentration of the gas is then converted to permeation units and the result displayed on the instrument screen. The system can be networked for remote collection of information.

The chamber may be configured for any thickness of sample using collars when the thickness or porosity of the sample causes lateral permeation. Any number of chambers may be fitted into an instrument, and a wide range of surface area chambers can be supplied . There are various or clamping systems options.

Remote Chamber Configuration

Remote Chamber Configuration

Where it is necessary to place the sample chamber in a remote location, for example a freezer, kiln or pressure chamber, a remote option is available. The remote chamber is supplied in an open frame and piped to the main instrument.

Seal Quality is Vital

The requirement to clamp samples is common across vapour permeability techniques and the quality of the seal is vital in achieving an accurate result. The diffusion chamber is usually circular and the sample under test is used to isolate the atmospheres in the two halves of the chamber from one other. Chambers can be adapted to components, enclosures, finished products, seams and even in situ edible films inside a pizza. There is no practical limit to the size of sample that can be measured, although a common size is around 50 cm².