Introduction

Introduction

The Versaperm Helium Permeability Meter Mk VI is a versatile permeability device offering a sensitive and accurate measurement of a material's helium vapour permeability. Its flexibility is demonstrated evident in the number of applications with which it is routinely tasked and the range of industries in which it is used – which range from Airship companies to standards laboratories and from multinational food and pharmaceutical companies to packaging companies, textile companies and universities.

The Versaperm Helium Permeability Meter Mk VI is not mass-produced, as are some of the instruments on the market. Each machine is carefully designed and manufactured to meet a customer's specifications and requirements. While this page covers common choices and some of the proven design options, we can leverage our experience to produce a completely new and dedicated design should it be required.

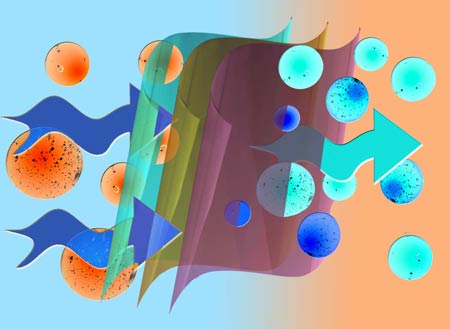

The diffusion chamber is divided into two sections by a test specimen. Dry nitrogen is passed through one upper part and helium is passed through the other. A gas sensor fitted in the nitrogen chamber is used to indicate a zero state. The upper chamber is then isolated and as helium diffuses through the sample, the level of helium increases, and the diffusion rate may be calculated. The display shows the changing reading and dynamically calculates the diffusion rate.

The Helium Permeability of solids up to 38 mm thick can also be measured

The Versaperm system is widely used on Films, Laminates, Rigid Materials, Coatings and Resins. Paint films and other surface treatments can also be measured by casting or applying them to typical substrates such as plywood, hardboard, etc

In most cases this instrument will provide the fastest technique for accurately measuring Helium Permeability.

In many cases, speed and accuracy are in competition, and the balance is set dependant on the customer's specific application requirements.

Measurement times are governed entirely by the time required to reach equilibrium conditions in the test specimen.

Even for low permeability materials, measurement time is short enough for use in Quality Control laboratories.

For very low permeability materials, the measurement rate and overall time increases .

For higher permeability materials, greater speed is achieved by using a lower surface area-measuring chamber, the measurement rate may be increased.

The original Permeability Meter was developed for measuring packaging materials with very low gas permeability transmission rates but less efficient barriers can also be measured with speed and accuracy.

The surface area of a standard diffusion chamber is 1/200m². This allows for the use of a range of sensors to produce reliable readings at very low levels.

The standard gas sensor is a katharometer to measure thermal conductivity. The alternative is a mass-spectrometer-based detector, which allows for a remote chamber. When using a mass spectrometer, a flow based measurement technique is used. We have experience of a wide variety of sensors, sourced from market leaders around the world, and are able to build an instrument around a sensor of the customer's choice, or advise on the sensors available for any gas. We recommend routine checks and an annual service at which time cleaning and a calibration of the electronic components is made.

Computerised Control

Computerised Control

The computerised control of the instrument allows for the automation of many parts of the process. Customised software is written for each instrument, which can be tailored to suit each customer's requirements.

Wide Range of Measurement Conditions

Chamber temperature is typically controlled to 0.1 °C from ambient -20°C to 60°C. Indicated temperature is accurate to 0.5°C. Other temperature ranges are available as an option.

Instrument Configuration Options

Within the temperature-controlled cabinet, there is a frame designed to accommodate a maximum of 3 chambers in whatever combination will suit the purchaser. Where mass spectrometry is used, external chambers may also be installed, for example if a measurement was to take place in a refrigerator.

For Helium Vapour permeqbility testing (gasses) click here