With the global market for footwear predicted to be worth US$430 billion by 2024, the modern fashion trends have never moved so fast or been worth so much. This, twined with the market's desire for increasingly high performance textiles, may have proved a boon for manufacturers - but it has brought with it a considerable strain on companies that need to introduce their new performance fabrics in shorter and shorter timescales.

Sadly this is made harder by the ISO standard (15496:2004) that covers the vapour permeability of textiles for footwear still relies on the traditional gravimetric measurement technique which normally takes several weeks to produce a single result! This time-scale is not p0ractical in such a rapidly moving fashion market and so we have introduced a fast instrumental system which can speedily measure vapour permeability, sometimes in as little as thirty minutes.

We also also produces a traditional system that enables manufacturers and developers to ensure full final ISO compliance.

We also also produces a traditional system that enables manufacturers and developers to ensure full final ISO compliance.

The headlong rush for new textiles, fashions and footwear has become an everyday part of the industry and to meet it our Versaperm Mark VI meter is fast, very accurate and easy to use. It can measure vapour permeability in as little as 30 minutes with some samples

The system gives accuracies in the Parts Per Million (PPM) range and is designed both to speed product and textile development as well as having the ability to provide smart quality control for materials and finished products.

Weatherproof footwear fabrics are typically natural materials, laminates or plain weaves with yarns coated with a durable, water repellent finish. Many also have a microporous or monolithic film coating or multi-layer combination. Today, these materials are produced in massive quantities worldwide.

Testing principle - ISO 15106-1 and ASTM F 2298-03

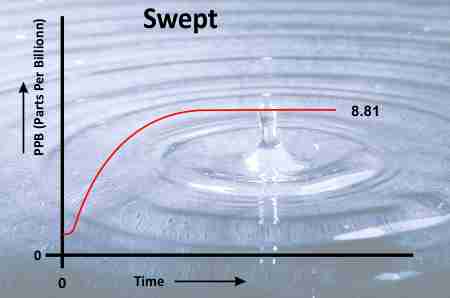

Based on ISO 15106-1 (and fully in line with ASTM F 2298-03), a dry chamber, at a specified relative humidity, is divided by a sheet of the test material from a wet chamber, where the atmosphere is saturated with water vapour at a known temperature. The water vapour flows through the specimen where it is measured by a sensor on the other side

The time taken for the humidity to increase by a given amount is measured and converted into a water vapour transmission rate.

Under ASTM F 2298-03 the test is split into two parts – first a diffusion test which takes place with zero pressure difference between the two chambers, and second a combined convective/diffusion test where a series of pressure gradients are applied to allow examination of the interaction of convective and diffusive transfer.

An example of the apparatus used to measure this is shown the diagram, and indeed represents the layout we at Versaperm use.

The diagram shows a transmission cell comprising two chambers, a lower (high-humidity) chamber and an upper (low-humidity) chamber the material sample is mounted between these to form a barrier

The lower chamber is connected directly to the reservoir - usually water in the case of footwear, (though the equipment can be used for any gas with a suitable sensor).

The upper chamber collects the vapour which has passed through the sample from the high-humidity side, and the humidity sensor is mounted over this chamber.

The ISO standard requires the transmission area to be between 5 cm2 and 100 cm2

For an article on vapour permeability of footwear in Innovations in textiles click