By Chris Roberts, Director Versaperm

As Donna Guinivan and Margareta Mildsommer have written about in the press, polymer seals play an important role in food and water applications. They were absolutely right - unfortunately it is only half the story.

As Donna Guinivan and Margareta Mildsommer have written about in the press, polymer seals play an important role in food and water applications. They were absolutely right - unfortunately it is only half the story.

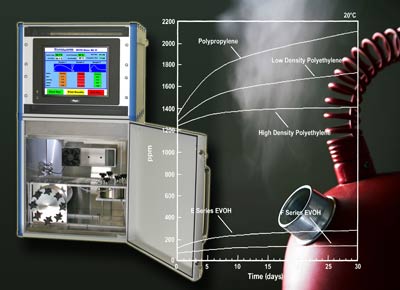

Polymers are very good at keeping liquid water out (or in!) but when it comes to water as a vapour some of them are extremely poor – hundreds of thousands of times worse than the barrier you would expect. The problem is that water as a vapour acts in a very different way to water as a liquid. Liquid water behaves well. Water vapour doesn’t, in fact it can behave downright badly – and in a completely counter-intuitive way. As an example, in some cases, making a seal tighter can actually let MORE water vapour through!

Freezer burn, as another example, is caused entirely by water vapour escaping from frozen products through the “waterproof” materials that contain them. Food spoilage, which costs the UK billions of pounds a year, is usually caused by water (as a vapour) leaving (or entering) the product. The right packaging material can prolong shelf-life and dramatically boost quality.

Different foods need the packaging to allow the water vapour and other gases to react differently to preserve the content Strawberries act in a completely different way to carrots or greens – which is why it takes a little thought to make Modified Atmosphere Packaging (MAP) works as well as it does.

The table below shows many of the widely used packaging materials and their water vapour (often the main concern) and other, food-critical, gases.

PET is widely used in the industry – yet it allows 10,000 times more water vapour through than polyamide. Polystyrenes are also widely used in food packaging - and they are 80,000 times worse!

Unfortunately the story becomes even more complicated when it comes to the finished product – for example the very act of forming the blister in a blister pack reduces the plastic’s ability to retain water vapour by 400% . The seal on products can be thousands of times worse than this. The only solution is checking the actual packaging, fortunately equipment and lab services are available to do this.

Let me give a practical example of the packaging preserving the product – in this case strawberries or raspberries. These are usually packaged in perforated-top containers. However the fruit “respires” within and the concentration of CO2 rapidly approaches the critical 10-15% level necessary to inhibit Botrytis growth.

This works well, however an alternative approach can make it even better - flushing the package with known gas mixtures and using packaging materials that have been tested for the inward and outward flow - not just of water vapour but of Oxygen, Nitrogen and Carbon Dioxide as well. This maintains the best environment for as long as possible. Normally this involves gas mixes 5-15% CO2, 2-5% O2, with N2 as the remainder. The CO2 generally rises during the first 12 hours and dramatically restricts Botrytis growth.

It is worth taking a very brief look at some of the widely used packaging materials:-

Low Density Polyethylene: An extremely versatile material with low water vapour permeability but high gas permeability.

Ethylene Vinyl Acetate, has superior sealing qualities and blended polyethylene can make a strong peelable seal.

Linear Low-Density Polyethylene (LLDPE): This has greater impact and puncture strength, tear resistance, elongation and resistance to cracking. It is commonly used for MAP.

High Density Polyethylene: with its higher softening point (than LDPE) it provides

Better a physical barrier buts not suitable as a thermoformable sealant layer, clarity is poor.

Polypropylene (PP) and Oriented Polypropylene (OPP): Gives a high water vapour and gas barrier and has excellent grease resistance.

Co-extruded Oriented Polypropylene (COPP): Is a good moisture barrier, gas barrier properties can be improved by coating it with PVdC. It can be used when gas flow is desired for MAP (Modified Atmosphere Packaging).

Inomers: Are similar to polyethylene but have a high tack and can seal through a level of surface contamination.

Ethylene Vinyl Acetate (EVA): Has high flexibility, and high permeability to water vapour and gases with excellent oil and grease resistance.

Polyvinylidene Chloride (PVdC): Used for MAP as a gas-barrier coating, often

sandwiched between other materials. It has outstanding barrier properties with low permeability to water vapour and gases.

Ethylene Vinyl Alcohol (EVOH): A moisture sensitive, very high gas-barrier material, again often sandwiched.

Polystyrene: A clear thermoplastic with a high tensile strength. It is brittle and a poor barrier to moisture vapour and gases.

High-impact Polystyrene: Opaque, thermoformable, and a moderately low gas-barrier.

PET: High clarity that forms and thermoforms well.

Using the most appropriate materials can dramatically extend the life of food products, boost quality, virtually eliminate freezer burn, reduce spoilage and thus boost profits. However it depends not just the materials you use, but on the way you make the seals – which can vary even on the same equipment on a daily basis. The best solution is to test the materials, the packaging and the finished products.

The question is, as my parents used to ask me, “Did you pass the test!”